Measurement and regulation of electrical energy

The purpose of the control systems is to optimize power peaks and thus naturally reduce the negotiated quarter-hour (technical) maximum and hourly consumption with a consequent reduction in monthly electricity payments. Peak reduction is implemented automatically, with the work forcibly suspended by the appliance in the critical quarter hour being replaced and used in the non-energy intensive quarter hour. This avoids losses in production and also results in significant permanent financial savings in the cost of electricity consumption.

Monitoring and measurement of secondary energy consumption

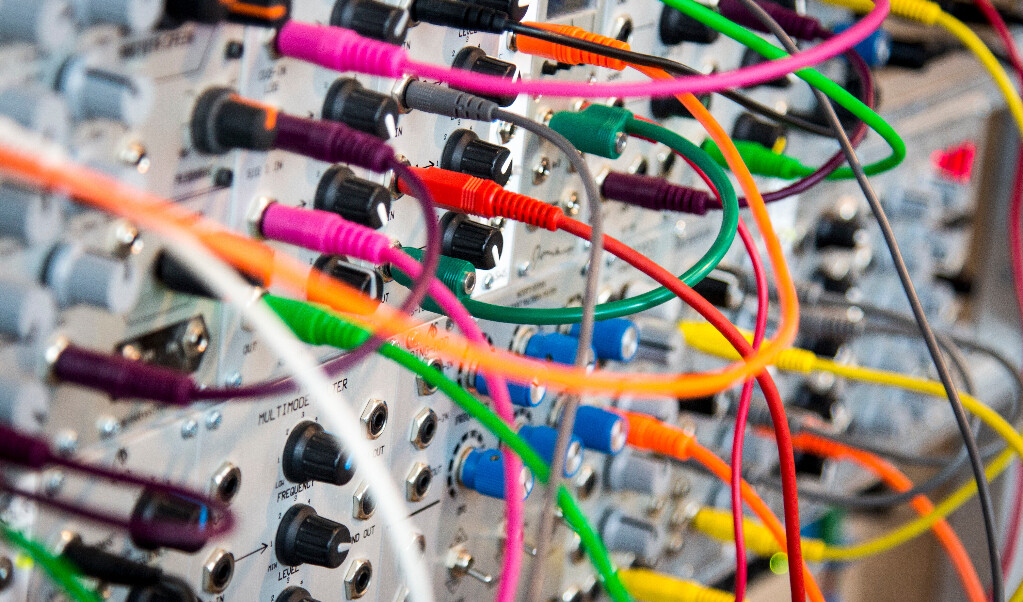

Any measurable variable can be included in consumption monitoring and measurement systems. In practice, the measuring point is usually equipped with a meter with pulse or analogue output. The output values from this meter are read into the system built on DOMINO XPU stations and further processed.

The monitoring systems for secondary measurements are most often designed as monitoring of secondary electricity meters [kWh], gas meters [m3], water meters [m3], temperature [°C], ... for individual

Read more: Monitoring and measurement of secondary energy consumption

Monitoring of production lines and work processes

Virtually any machine, equipment or production line can be included in workplace and production line monitoring systems. The monitored workplace can be supplemented with a visualization LCD screen or STAB2 panel. One screen or panel is usually used for a single workstation to provide quick information to the workstation operator. The standard display shows the PLAN (number of pieces), PERFORMED (number of pieces) and TREND converted value of plan execution in %. The measured values are loaded into the

Read more: Monitoring of production lines and work processes